We are proud to be among the highest-ranked companies globally for sustainability holding an EcoVadis Platinum rating – a confirmation of our sustainability work.

Our work with responsible procurement is grounded in international conventions and frameworks such as the UN Guiding Principles, the OECD Guidelines for Multinational Enterprises, ILO standards and the UN Global Compact. The process covers areas within climate, circularity and resource use, as well as social impact.

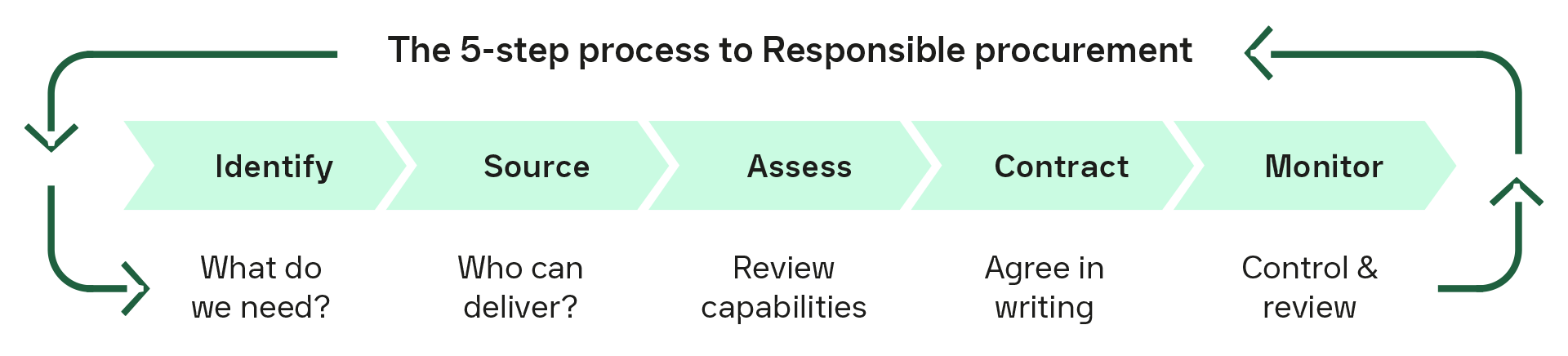

We work systematically and risk-based to identify, prevent and manage risks. Through our five-step model – identify, source, assess, contract and monitor – we integrate our requirements throughout the entire procurement process to mitigate risks, strengthen knowledge and drive improvements in the supply chain.

In the third step, Assess, we apply our risk-based due diligence process, which consists of three levels. Depending on the level of risk, we implement different actions, such as supplier self-assessments, factory audits or capacity building activities. In some cases, if the supplier shows no willingness to improve, the partnership may be terminated.

If a supplier meets the requirements in the due diligence process, we move on to step four, Contract. At this stage, we sign contracts in which the supplier commits to our Supplier Code of Conduct.

In the fifth step, Monitor, we verify that suppliers continue to meet our standards. We conduct supplier risk mapping regularly as part of our due diligence process. Our method follows the OECD guidelines and aims to identify, prevent, mitigate and remedy adverse impact in the supply chain.

Level 1: Risk mapping

All suppliers undergo at least an annual risk assessment using the RBA’s Risk Assessment Tool. This assessment covers areas such as working conditions, health and safety, environment, business ethics, and management systems. Suppliers identified as high-risk proceed to the next level for more in-depth review.

Level 2: Self-assessments (SAQs)

Depending on the potential risk and supplier type, we use self-assessments such as the RBA corporate SAQ, RBA facility SAQ or Dustin’s Supplier Sustainability Assessment Questionnaire (SSAQ). These questionnaires provide opportunity for the suppliers to demonstrate their compliance to our sustainability requirements on human and labour rights, occupational health and safety, environmental and ethics. Next level due diligence methods can be triggered in Level 3 depending on the identified potential risks.

Level 3: Verification

For high-risk suppliers identified from our due diligence process, there are multiple further due diligence methods that can be chosen such as audits, digital and in-person trainings, surveys, supplier dialogues, escalations, sharing best practices, etc. In severe cases, or if suppliers do not take necessary corrective actions, we may terminate the business relationship.

A key part of our risk-based due diligence process is direct dialogue with workers in the value chain. Through factory visits, trainings, collaboration with organisations such as Electronics Watch, and other dialogues we gain insights that help us identify risks and make informed decisions.

We have clear procedures to address situations where we have caused, contributed to, or are linked to negative impacts. Corrective actions are developed in collaboration with external experts and tailored to local conditions to ensure that the needs of those people or areas that are affected are prioritised.

As an important channel to identify potential risks, we promote an anonymous whistleblower system in multiple languages, with QR codes placed in factories producing our private label products for easy access. We also require all our suppliers to have their own fair and accessible grievance channels.

Our procurement department analyses results from each level of our risk-based due diligence process. Once potential high-risk is identified, sustainability team will be consulted to determine if and which further due diligence method will be triggered. Dedicated resources, including local partners in supplier countries, work on follow-up, capacity building, and improvements directly with factories manufacturing our private label products.

KPIs and targets (2024/25)

Want to know more about our due diligence work? Read our Dustin Responsible Supply Chain Report here, where we annually report on how we work with due diligence and responsible sourcing in the supply chain.

We are proud to be among the highest-ranked companies globally for sustainability holding an EcoVadis Platinum rating – a confirmation of our sustainability work.

Read our latest sustainability report here to learn more about our sustainability work